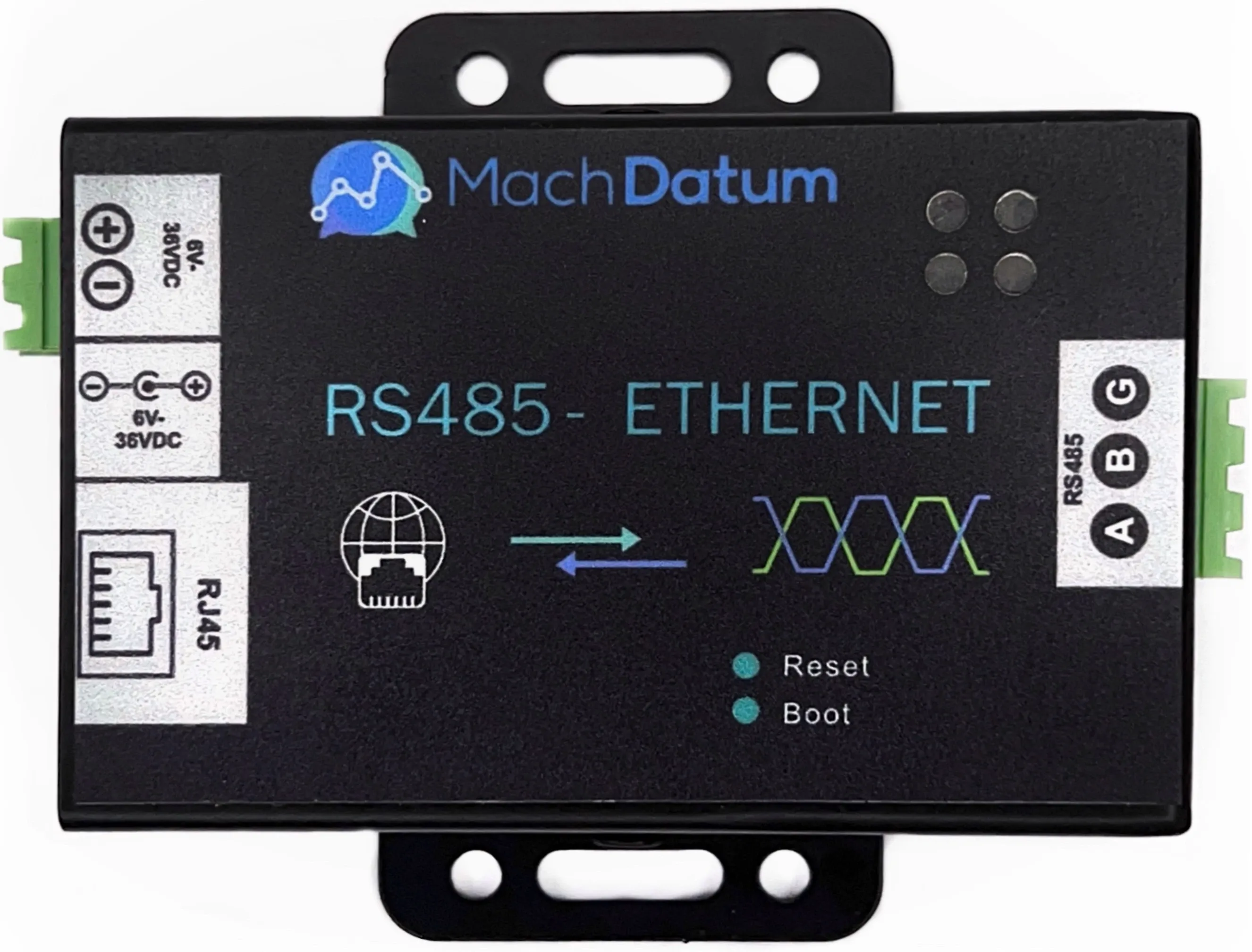

Introducing the MDIM-485 RTU to TCP Converter

In today’s fast-paced industrial world, bridging the gap between legacy systems and modern digital networks isn’t just a nice-to-have — it’s an absolute necessity. As factories and field operations evolve to meet the demands of Industry 4.0, one critical challenge stands out:

| How do you connect old, serial-based devices with modern, Ethernet-based control systems?

That’s where the MDIM-485 comes in — a smart, compact, and powerful device designed to make this transition seamless. In this blog, we’ll explore what the MDIM-485 is, why industries rely on it, how it works internally, and how it plays a pivotal role in modernizing industrial communication systems.

What is the MDIM-485?

The MDIM-485 is a high-performance Modbus RTU to Modbus TCP converter that enables communication between devices using the RS-485 serial interface and those operating on Ethernet networks using TCP/IP.

In simpler terms, it acts as a translator. It allows a Modbus TCP master (like a SCADA, HMI, or PLC) to communicate with Modbus RTU slave devices (like energy meters, VFDs, sensors) over Ethernet.

It helps industries retain their investment in legacy serial devices while still moving toward Ethernet-based centralized control systems.

Why Do We Need an RTU to TCP Converter?

1. Seamless Legacy Device Integration

A large number of industrial devices — like sensors, meters, and actuators — still operate using the RS-485 Modbus RTU protocol. The MDIM-485 acts as a bridge, allowing these devices to plug into modern control systems via Ethernet, effortlessly.

2. Standardized Communication Infrastructure

Ethernet has become the backbone of factory-floor communication. The MDIM-485 supports this shift by enabling TCP-based systems to interface with RTU-based devices, standardizing communication across the board.

3. Reliable Long-Distance Communication

Compared to traditional serial cabling, Ethernet offers better signal integrity and supports longer distances — especially useful in larger facilities with structured cabling systems.

4. Simplified Centralized Control

With MDIM-485, multiple field devices can be connected to a single Ethernet link. This makes it easier to control and monitor devices centrally, through SCADA systems or other controllers.

How Does It Work Internally?

Here’s a quick look under the hood at how the MDIM-485 handles protocol conversion — all in real-time and with minimal latency:

- TCP Client Initiation: A TCP client (like SCADA software) connects to the MDIM-485 via its Ethernet port using the Modbus TCP protocol.

- TCP Request Parsing: The device receives and parses the incoming Modbus TCP frame, extracting the Modbus PDU and slave address.

- Serial Transmission: This data is then reformatted into a Modbus RTU frame and transmitted over RS-485 to the target slave device.

- RTU Slave Response: The addressed RTU device replies with the requested data or an acknowledgment.

- TCP Response Generation: The MDIM-485 captures the RTU response, wraps it in a Modbus TCP frame, and sends it back to the TCP client.

All of this happens smoothly, maintaining speed, accuracy, and system integrity.

Key Features of the MDIM-485

- Seamless Modbus RTU to Modbus TCP Bridging

- Consistent Throughput for Modbus TCP

- Transparent Protocol Conversion

- User-Configurable Modbus Parameters

- Support for Multiple RTU Slaves

- Reliable Performance at 10 Mbps Ethernet

- Enhanced Electrical Protection

- Supports dual power input options

- Wide Operating Voltage Range

- Compact, Industrial-Grade Design

- DIN-Rail and Panel Mounting Options

Where Can You Use the MDIM-485?

The MDIM-485 is built for versatility and is ideal for a wide range of industrial and infrastructure applications, including:

- Factory Automation

- Building Management Systems (BMS)

- Energy Monitoring Systems

- Water and Wastewater Treatment Plants

- Process Control Panels

- Remote Terminal Units (RTUs) in substations

In short, any application that uses legacy serial field devices but requires centralized or Ethernet-based control can benefit from deploying the MDIM-485.

Industrial-Grade by Design

Built with durability and real-world demands in mind, the MDIM-485 offers:

- DIN-rail mountable enclosure for easy installation

- LED indicators for TX/RX, power, and link activity

- Wide input voltage range for flexible deployment

- Robust Ethernet PHY with built-in ESD protection

- Plug-and-Play Deployment

Final Thoughts

In the journey toward digital transformation and smarter factories, industrial teams need reliable, cost-effective tools that help bridge the old and the new.

The MDIM-485 is exactly that — a plug-and-play solution that allows you to:

- Preserve and continue using existing RS-485 field devices

- Upgrade to Ethernet-based control networks

- Enable centralized and remote monitoring

- Ensure compatibility with SCADA, PLCs, and cloud systems

Whether you're a system integrator, plant manager, or automation engineer, the MDIM-485 gives you the power to modernize your infrastructure — without leaving legacy investments behind.