Ever tried explaining a Quality Management System (QMS) to someone at a dinner party? You’ll get that glazed-over look faster than you can say “ISO 9001.” Now try mixing in the term “Industrial IoT” — and watch the confusion doubles.

But here’s the truth: in today’s hyperconnected manufacturing world, companies that don’t combine QMS with Industrial IoT (IIoT) are leaving serious money—and opportunity—on the table.

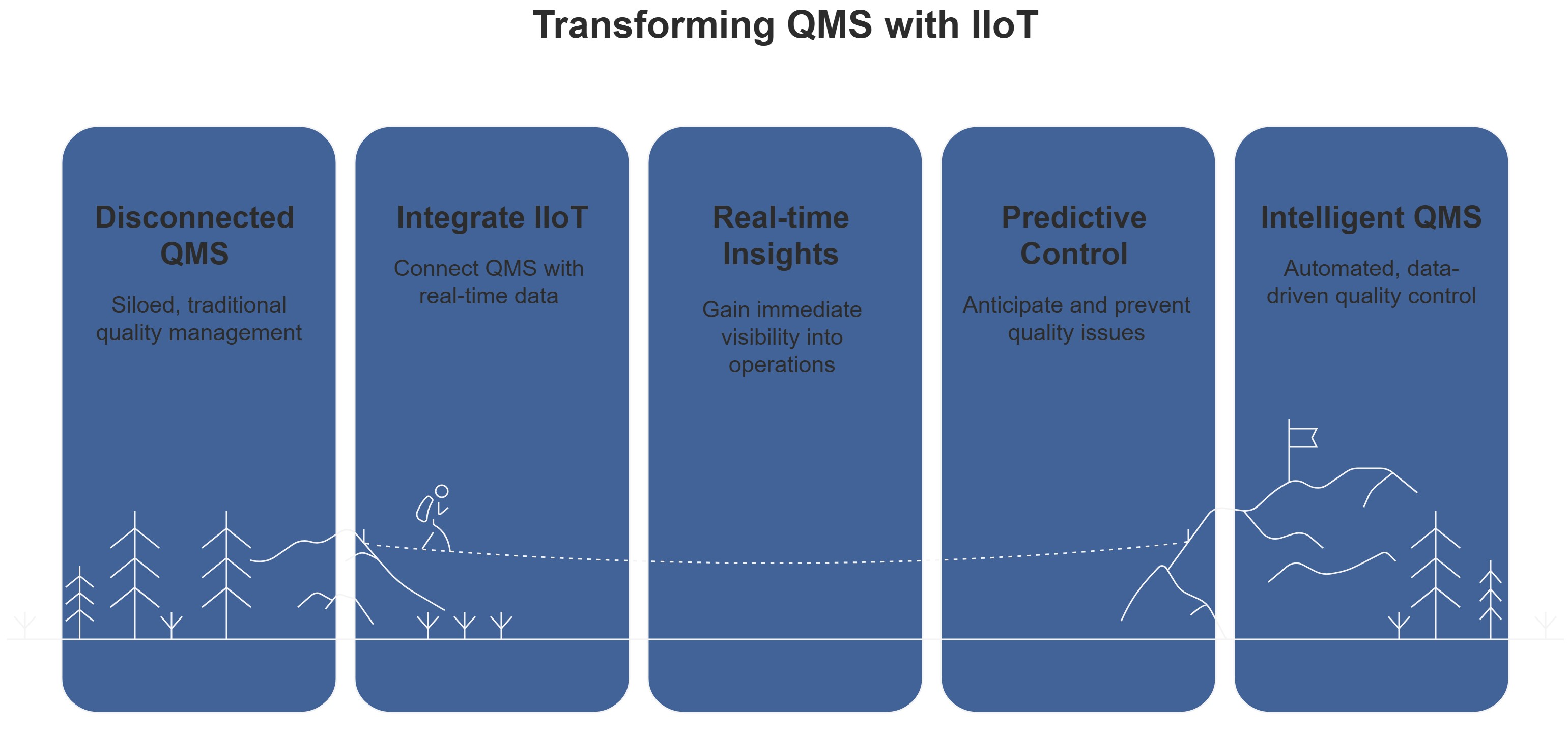

This isn’t just about reducing paperwork or avoiding compliance fines. It’s about real-time insights, predictive quality control, and automated decision-making that can fundamentally change how you operate.

Let me show you why QMS powered by IIoT isn’t just a smart move—it’s a transformational one.

The Business Impact of Implementing QMS in Industrial IoT

Real-Time Quality Monitoring and Product Consistency

In the age of IIoT, sensors continuously capture data from machines, production lines, and products themselves. A Quality Management System integrated with these streams can analyze performance as it happens, flag anomalies instantly, and even trigger corrective actions automatically.

It’s no longer about detecting defects after the fact—it’s about preventing them before they happen.

Companies implementing QMS see dramatic improvements in their defect rates - often by 50-70% within the first year alone. Take Toyota, for example. Their legendary QMS reduced defects to less than 10 parts per million. That's not just impressive - it's game-changing for their bottom line.

The numbers tell the story better than I could:

Before QMS Implementation

- 3-5% defect rate

- Inconsistent product performance

- High variance in manufacturing

After QMS Implementation

- 0.5-1% defect rate

- 98% consistency in product specifications

- Standardized processes across operations

What's crazy is how fast these improvements happen. Most companies see tangible results within 3-6 months of proper QMS implementation.

Boosted Customer Satisfaction and Predictive Service

When production lines are monitored in real-time, you can guarantee output quality, ship faster, and fix issues before the customer even notices.

Customers feel the difference—and respond to it.

- 25–40% jump in satisfaction scores

- Repeat purchases increase by 22%

- Referral rates double in under 18 months

With IIoT-driven QMS, you're no longer guessing what went wrong. You're tracking every data point and responding proactively, turning first-time buyers into loyal advocates.

Proactive Risk Mitigation and Seamless Compliance

Regulatory compliance in industries like automotive, pharma, aerospace, or food manufacturing is non-negotiable. But it's also a minefield.

IIoT-enabled QMS gives you real-time documentation, automatic traceability, and built-in audit trails. No more scrambling for files or manual logs.

Companies that implement this system see:

- 65% fewer compliance violations

- 83% lower cost of managing quality audits

- 77% reduction in critical incidents and recalls

In IIoT environments, your QMS becomes your quality control nerve center, ensuring problems are prevented—not reported after the damage is done.

Popular Frameworks Supporting QMS in IIoT

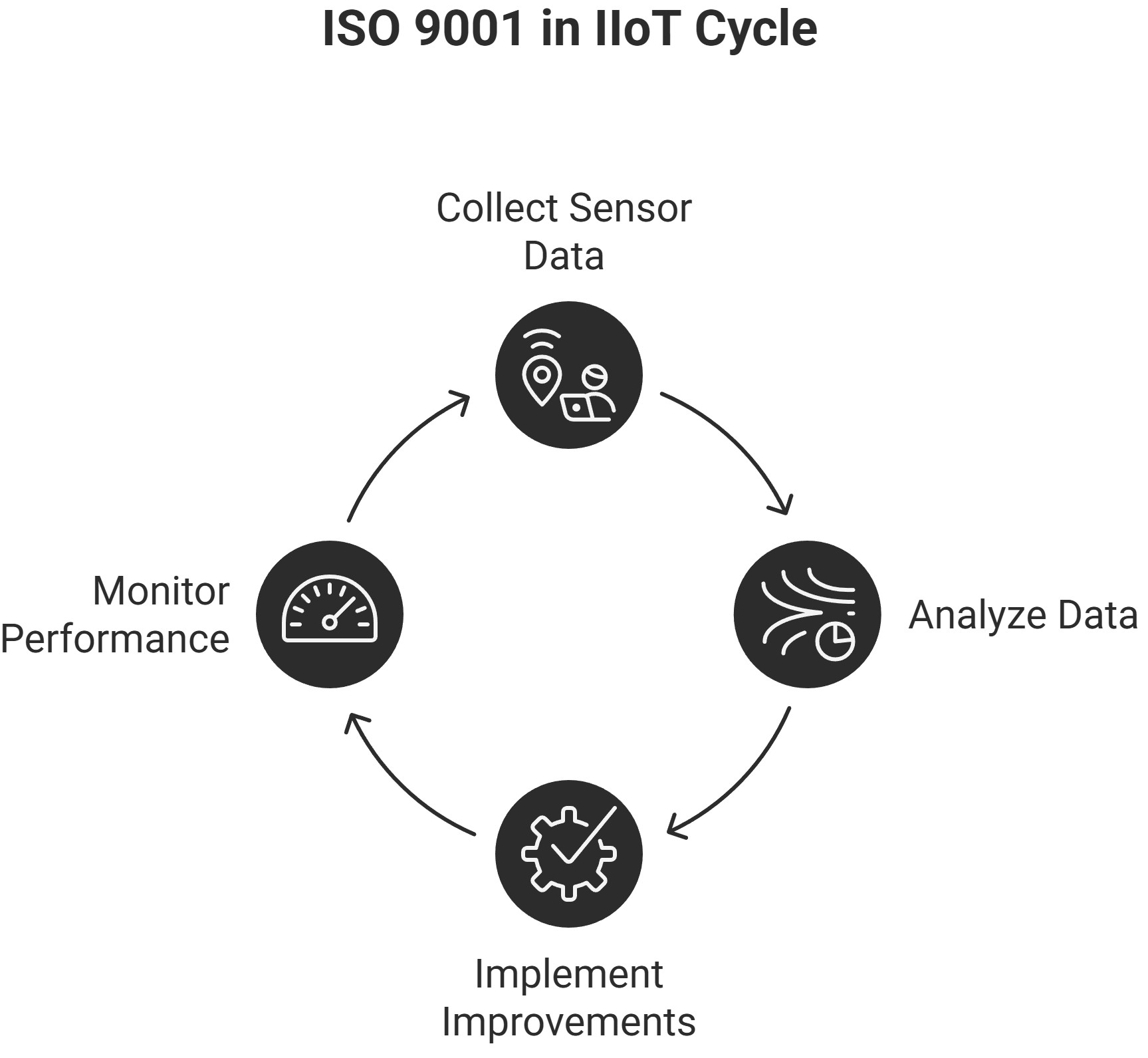

ISO 9001: Now Smarter with Sensor Data

ISO 9001 remains the global benchmark for quality, but in an IIoT context, it evolves from being a static checklist to a live framework connected to machine-level data.

By integrating sensor feedback, ISO 9001 processes become more agile:

- Performance metrics update in real-time

- Root cause analysis happens faster

- CAPA (Corrective and Preventive Actions) is automated

With the 2015 update emphasizing risk-based thinking and data-driven decisions, ISO 9001 + IIoT is a natural fit for smart factories.

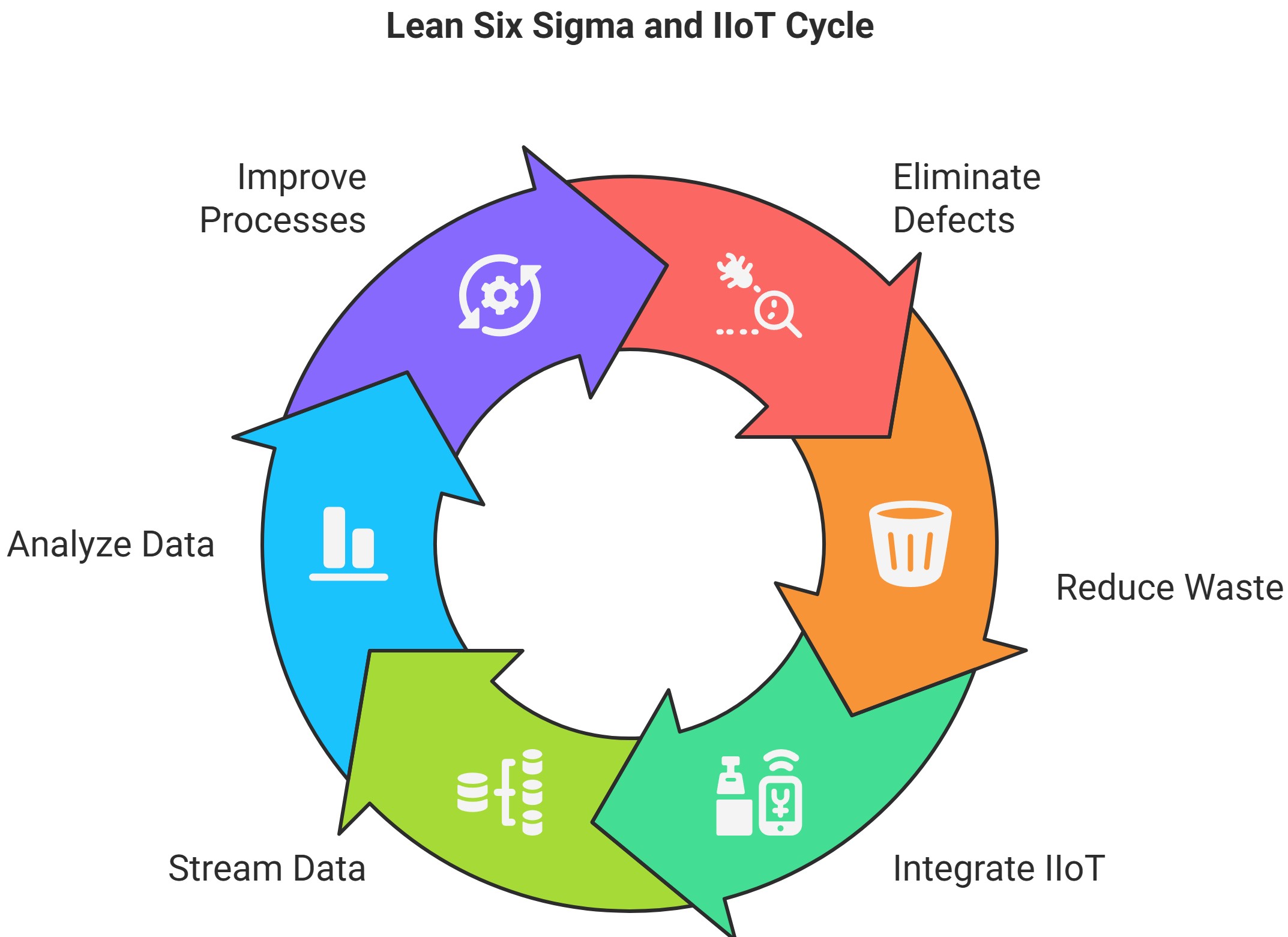

Lean Six Sigma + IIoT: Hyper-Optimized Manufacturing

Lean Six Sigma already helps eliminate defects and waste. Add IIoT, and it supercharges the process.

Imagine:

- Defect data streamed in real-time

- Statistical process control dashboards updating automatically

- AI-powered root cause suggestions based on real-time data

The classic DMAIC approach becomes smarter and faster:

- Define: Based on live performance KPIs

- Measure: From automated sensors

- Analyze: Using IIoT analytics

- Improve: With real-time interventions

- Control: Monitored continuously by smart devices

This isn't just Six Sigma—it's Six Sigma 4.0.

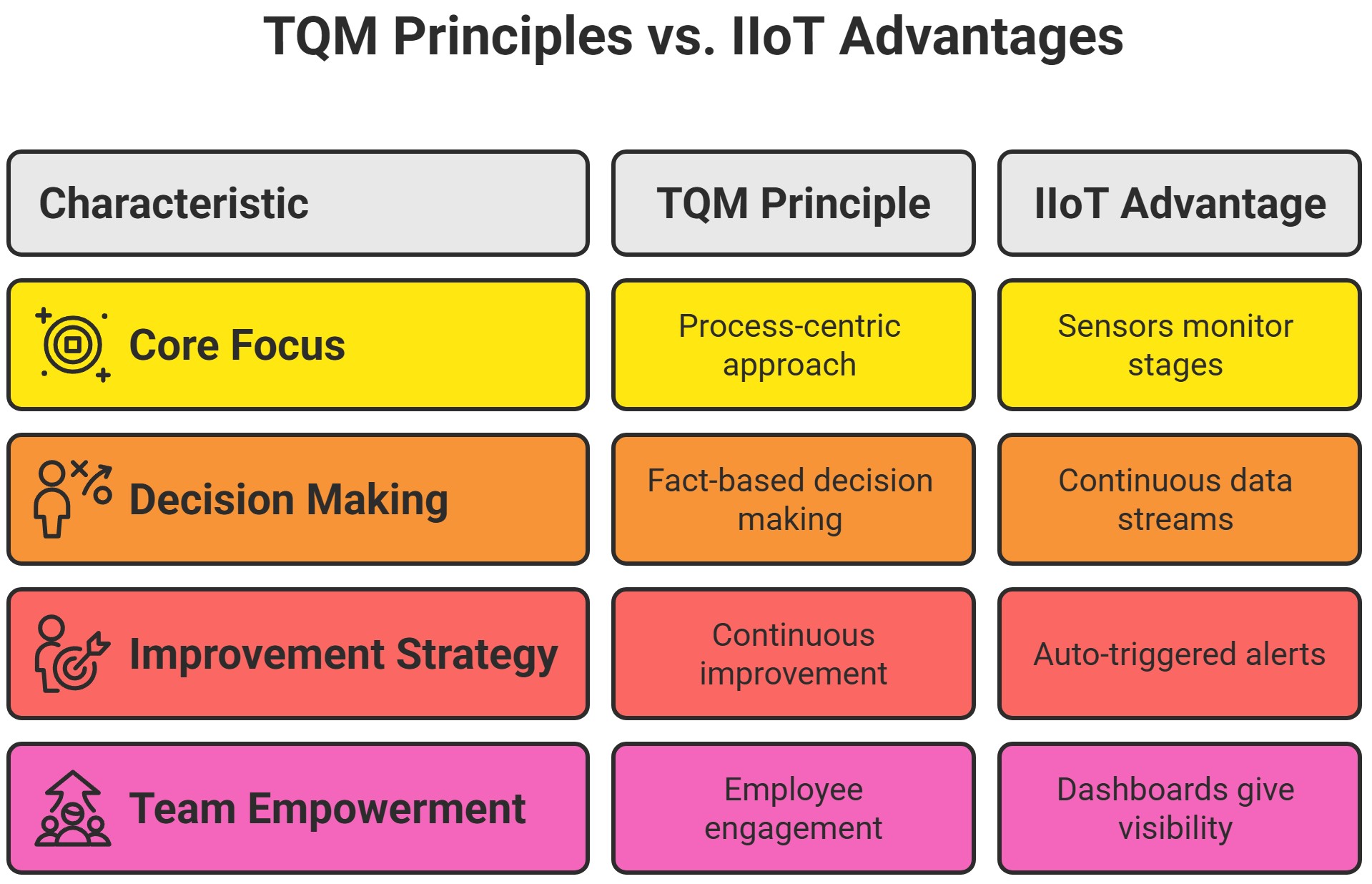

Total Quality Management (TQM) in the Digital Era

TQM's holistic principles thrive when paired with IIoT:

Industrial IoT allows TQM to move from theory to real-time practice—where every employee can see how their work impacts quality metrics, live.

Conclusion: Why a QMS is the Missing Link in Industrial IoT

Industrial IoT is revolutionizing how factories operate—real-time data, smart sensors, predictive analytics—all driving efficiency. But without a solid Quality Management System (QMS) in place, all that data is just noise.

A modern QMS in the IIoT era isn't just about documentation and audits. It becomes a live, dynamic system that taps into machine-level data, flags quality deviations instantly, and drives decisions based on real-time performance—not guesswork.

Whether it's reducing downtime through predictive maintenance, auto-triggering corrective actions from sensor alerts, or standardizing quality across smart factories, the synergy between QMS and IIoT is undeniable.

Here’s the bottom line:

IIoT gives you the visibility; QMS gives you the control.

In a high-stakes industrial environment where even a minor defect can ripple through supply chains, combining these two forces can mean the difference between costly recalls and continuous improvement.

If you're already investing in IoT technology, don’t leave quality as an afterthought. Integrate QMS into your digital strategy, and turn your plant into a self-correcting, customer-winning machine.

Quality Management Systems aren't just corporate bureaucracy, but actual game-changers that transform how businesses operate. Think about it. Your customers expect perfection. Your competitors are optimizing everything. Meanwhile, you're still putting out fires instead of preventing them. A proper QMS fixes all that.